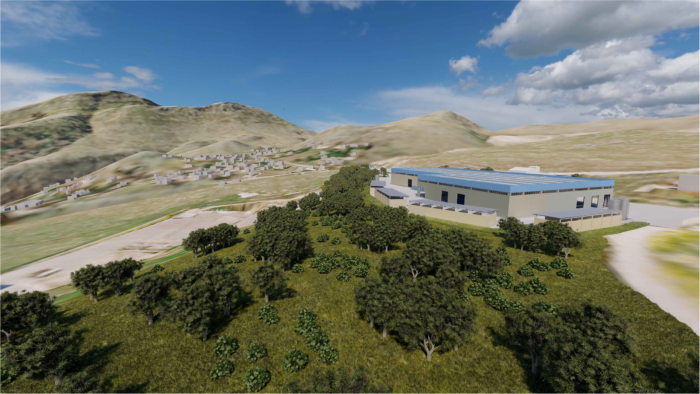

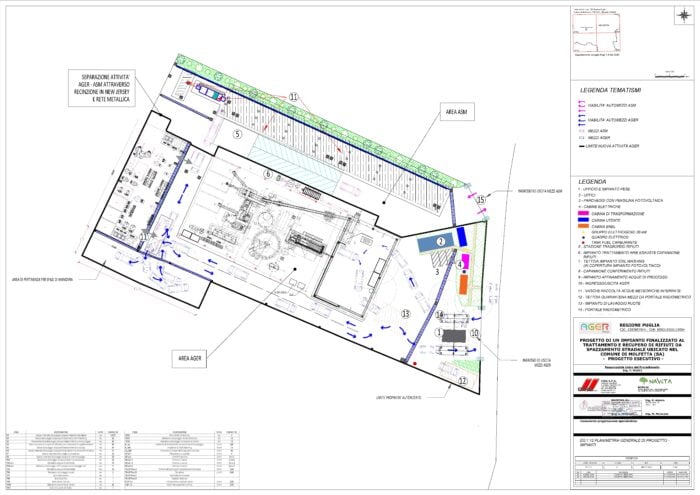

Ensure access to affordable, reliable, sustainable and modern energy for all

The pre-selection plant of mixed waste is divided into four parallel lines, each of which

comprises a pre-selection stage consisting of a coarse shredding, a primary screening,

a separation of ferrous and non-ferrous metals and a pressing of the coarse material,

and a refining step of the organic waste consisting of a secondary screening, with the

production of an underscreen to be biologically stabilized and an overscreen to be

processed with ballistic and infrared separation of recyclable materials. The system

doesn’t require the use of personnel for the sorting operations, which are conducted

exclusively automatical and managed by an operator from the control room. From the

undifferentiated M.S.W. the process allows the separation of the following: plastics to

be recycled; iron and aluminum to be later in foundries; organic material to be stabilized

for covering landfills or environmental remediation; material with high calorific value and

pressed into bales for disposal in landfill or for recovery as fuel in incinerators.

The factory shed is constantly kept under negative pressure in order to ensure the

health of the workplace. The air treatment system is constituted by a scrubber (washing

tower type) and a biofilter capable of returning the air in the atmosphere in accordance

with the most stringent levels set forth by law.

An implementation phase is also in place, which is aimed at the refining of the

screening material coming from the primary and secondary screening and waste of the

ballistic and optical separation; this material is the so-called RDF (Refuse Derived Fuel),

a “product” that will be inserted in the chain of the fuels used in cement plants, power

electrical stations, etc.