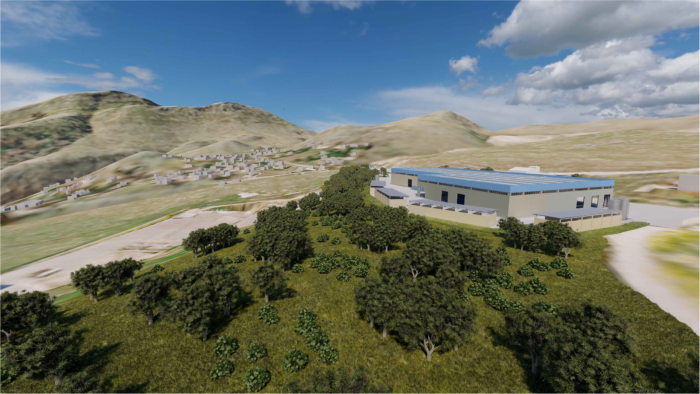

The proposed plant layout has the main objective to develop the production of compost,

obtained through a biological treatment of the organic fraction of the waste coming from

the separate collection.

The plant, authorized with D.D.S. n. 120 of 12/02/2014 and subsequent D.D.G. n. 1212 dated

05/09/2016, has a maximum capacity of 70.000 t/year has been defined for waste R13

and R3 as indicated in Annex C of the fourth part of Legislative Decree No. 152/2006.

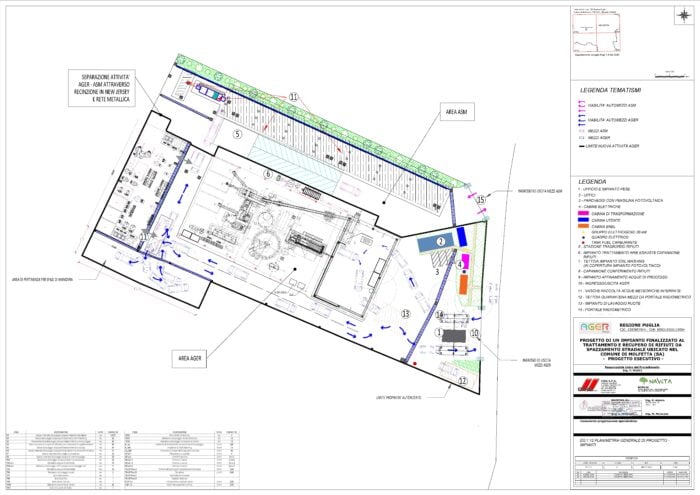

The different activities that take place inside can be defined as follows:

- Provision and mechanical pre-treatment of waste;

- Accelerated bio-oxidation in aerated static heaps;

- Ripening in upturned and aerated heaps.

The duration of the biological process must not be less than 90 days and in the first phase

includes a accelerated bio-oxidation, followed by a second phase of maturation in heaps.

The process technology for accelerated bioxidation is a static type with forced aeration of

the material and takes place within n. 10 biocells in reinforced concrete ensures a rapid

opening / closing of doors.

The maturation phase takes place inside a shed where 10 heaps are placed which are

periodically turned by means of a revolving means.

Finally the material is screened for a final refining: the overage is used as a structuring

and the under-size materials are placed in static heaps until the days necessary for

stabilization are reached.

The quantity of product is about 21.000 t/year and is stored under a side-opened steel

structure with a perimeter wall of 3.00 m height. The plant has been classified by a series

of systems for the mitigation of emissions in the various environmental sectors that the

activity in question could generate.