Ensure access to affordable, reliable, sustainable and modern energy for all

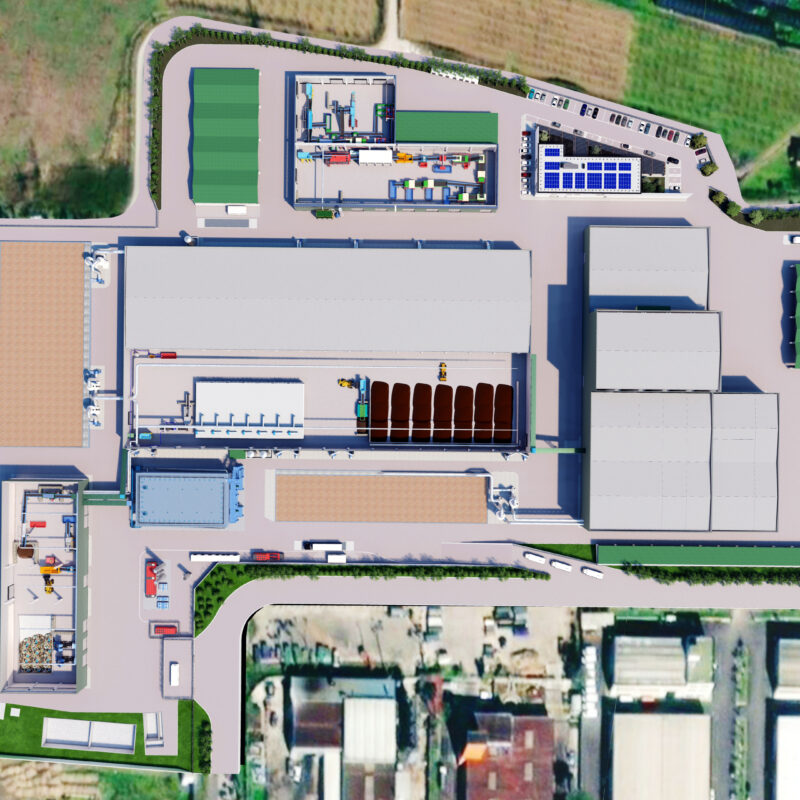

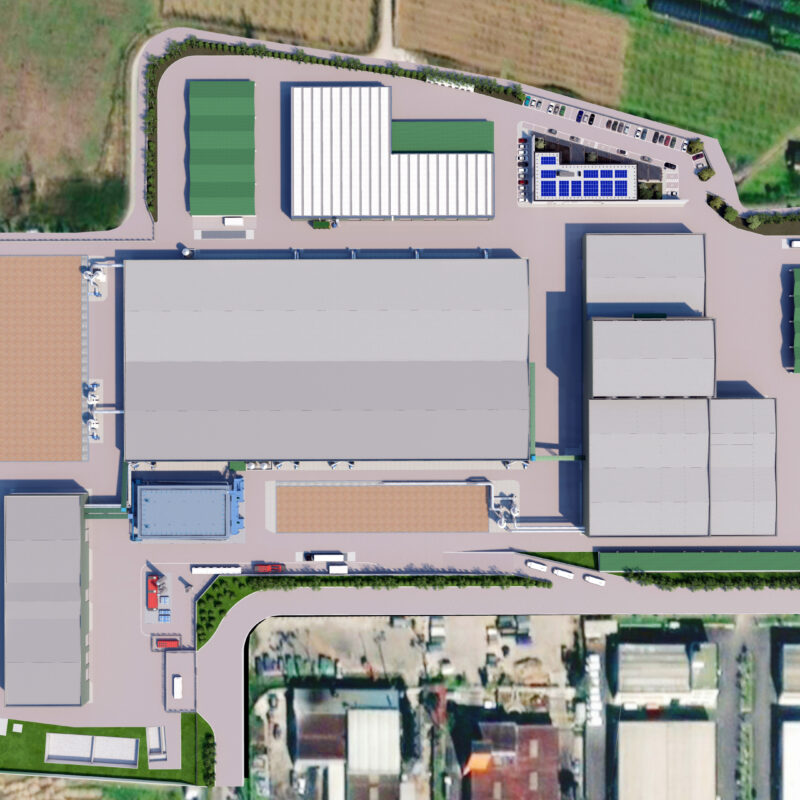

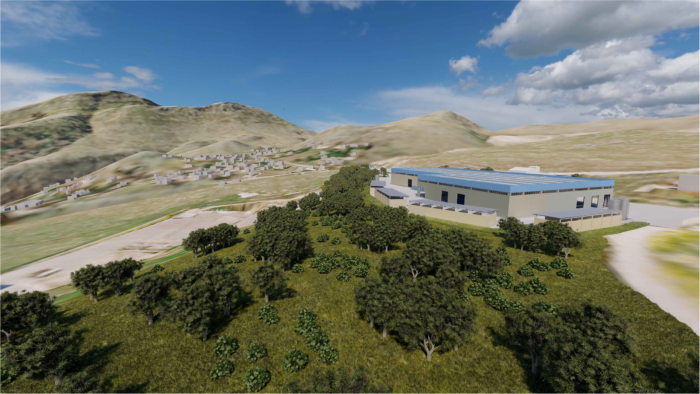

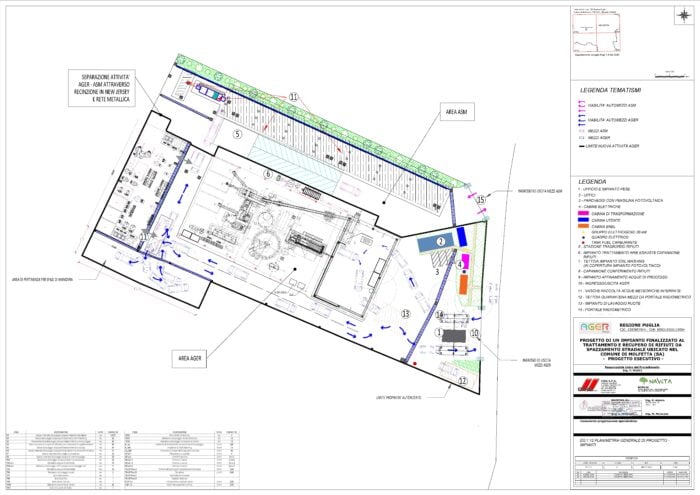

Making the most of the EU Recovery and Resilience Facility (RRF) instrument, the project provides an upgrade to the plant layout in order for it to meet the increasingly stringent environmental regulations and maximize recovery and recycling rates. The initiative broadly contributes to enhancing the integrated cycle of urban waste.

Location

Giugliano (NA)

Data

Type of service:

Technical and economic feasibility design

Design period:

December 2021

Technical data

Total site surface:

60.000 m²

Aerobic-anaerobic OFMSW section

Treatment capacity: 75.700 t/year

Produced Compost: 10.500 t/year

Produced Biomethane: 600 Sm3/h

Paper and cardboard recovery line

Treatment capacity: 37.200 t/year

Plastic material bales: 2.400 t/year

Paper and Cardboard bales: 29.000 t/year

Glas recovery line

Treatment capacity:77.000 t/year

Green glass cullet: 26.250 t/year

Flint glass cullet: 26.250 t/year

Amber glass cullet: 13.130 t/year

Metals (ferrous and non-ferrous): 875 t/year

The plant produces biomethane for the transport sector and compost for agricultural use in compliance with European and national regulations (EU regulation EN:13432 and the new European fertilizer regulation 2019/1009).

The revamp will include three process lines:

- An aerobic-anaerobic treatment section for the Organic Fraction of the Municipal Solid Waste (OFMSW) that will recover high-quality compost and biomethane;

- A section for the recovery of paper and cardboard coming from municipal solid waste segregated at source;

- A section for the recovery of glass coming from municipal waste segregated at source (colour-sorted glass, cullet production).

The aerobic-anaerobic process line provides a waste treatment capacity equal to 57.000 t/y of OFMSW, and 18.700 t/y of green waste. The section consists of:

a) A reception bunker followed by mechanical pre-treatment of incoming waste;

b)An anaerobic digestion section, where biomass undergoes a biochemical conversion producing biogas and a residual liquid (digestate);

c) A digestate mechanical dewatering section, with subsequent flocculation and flotation treatment followed by a leachate treatment plant;

d)A composting section for the aerobic stabilization of the solid digestate, thus obtaining a quality compost;

e) An up-grading unit of the biogas produced by anaerobic digestion to bio-methane production.