Ensure inclusive and equitable quality education and promote lifelong learning opportunities for all

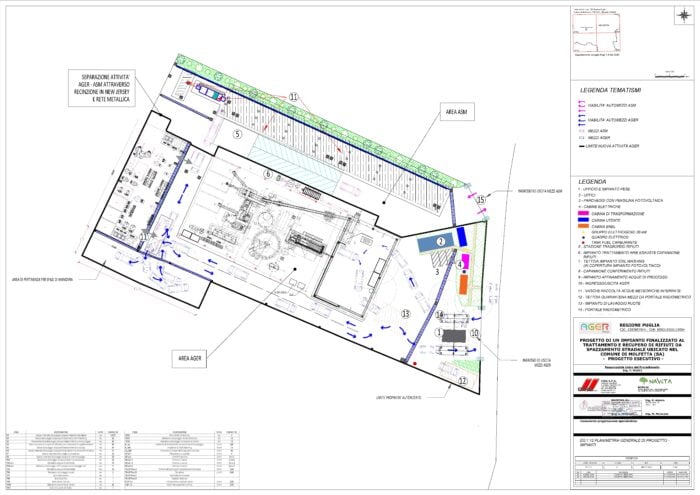

The initiative broadly contributes to enhancing the integrated cycle of urban waste.

Location

Lecce (LE)

Data

Type of service:

Technical and economic feasibility design

Design period:

December 2021

Technical data

Total site surface:

53.819 m²

Aerobic-anaerobic OFMSW section

Treatment capacity: 50.000 t/year

Produced Compost: 7.200 t/year

Produced Biomethane: 410 Sm3/h

The plant produces biomethane for the transport sector and compost for agricultural use in compliance with European and national regulations (EU regulation EN:13432 and the new European fertilizer regulation 2019/1009).

The project will include two process lines:

- An aerobic-anaerobic treatment section for the Organic Fraction of the Municipal Solid Waste (OFMSW) that will recover high-quality compost and biomethane;

- A wastewater and leachate treatment section that will reduce sludge to be disposed and recover clarified water.

The aerobic-anaerobic process line provides a waste treatment capacity equal to 50.000 t/year, 40.000 t/y of OFMSW, and 10.000 t/y of green waste. The section consists of:

a) A reception bunker followed by mechanical pre-treatment of incoming waste;

b) An anaerobic digestion section, where biomass undergoes a biochemical conversion producing biogas and a residual liquid (digestate);

c) A digestate mechanical dewatering section, with subsequent flocculation and flotation treatment followed by a leachate treatment plant;

d) A composting section for the aerobic stabilization of the solid digestate, thus obtaining a quality compost;

e) An up-grading unit of the biogas produced by anaerobic digestion for bio-methane production.

The WWTP will have a daily treatment capacity of 100 m3/day and includes a MBR (Membrane Bioreactor) treatment section for the oxidation of suspended biomass and the removal of ammonia nitrogen, followed by two units of ultrafiltration and reverse osmosis to ensure a high-quality output. The concentrate is sent to an evaporator for a further volumetric reduction and it will be shipped to duly authorized third-party plants.

Last but not least, an exhausted air treatment system (scrubber, biofilter, and bag filters); will ensure gaseous-effluent compliance with EU and local regulations.