Ensure access to affordable, reliable, sustainable and modern energy for all

The project’s objective is to establish the guidelines for designing a prototype plant for the recovery of BEV (Battery Electric Vehicle) batteries, transforming them into valuable secondary raw materials such as aluminum, copper, plastics, electrolytes, and Black Mass (BM).

It is estimated that by 2030, a total volume of approximately 200,000 tons of BEV batteries will have accumulated for recycling. Therefore, it is necessary to develop a sustainable recovery supply chain in line with the circular economy paradigm.

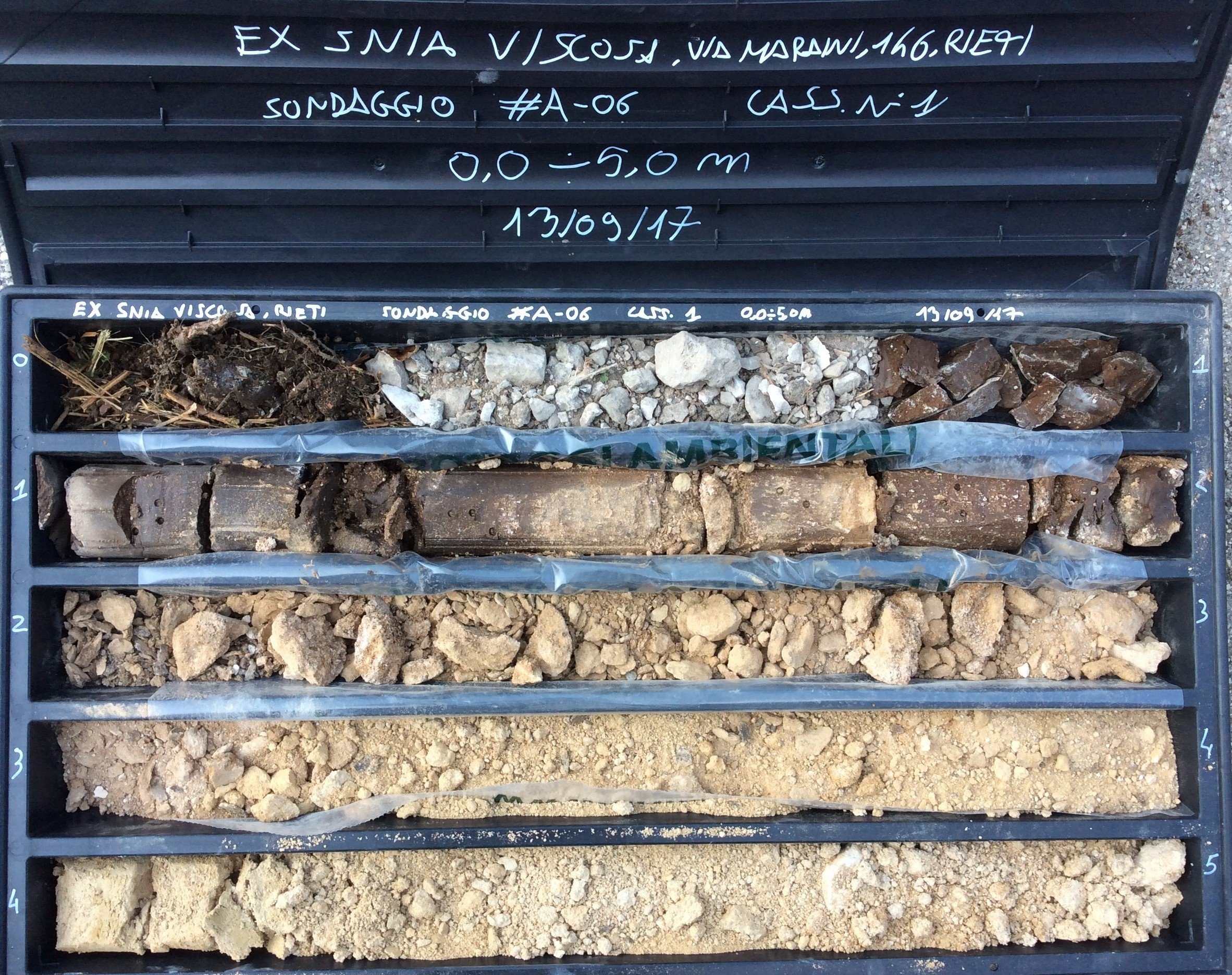

The project was developed on a conceptual flat, greenfield area with dimensions dictated by the overall operation of the plant platform, considering roads, storage areas, process areas, staff rooms, storage warehouses, plant areas, depots, parking lots and green areas.

The project was developed on a conceptual flat, greenfield area with dimensions dictated by the overall operation of the plant platform, considering roads, storage areas, process areas, staff rooms, storage warehouses, plant areas, depots, parking lots and green areas.

Each Battery Pack (BP) can have a second life, returning a significant portion of the valuable metals it contains, which, once selected and refined, can re-enter the production cycle, providing a perfect example of a circular economy.

The recovery process and the related civil and plant engineering works were developed in a linear fashion, following the recovery process: from arrival at the facility, inspection and selection, storage, treatment and recovery processes, separation of the materials, and finally their storage in the pre-shipping areas.

The project envisions development in two distinct phases based on treatment potential. Phase 1 has been envisioned, which includes design solutions and sizing for a treatment capacity of 10,000 t/year, while Phase 2 envisions doubling the surface area and plant equipment to reach a treatment capacity of 20,000 t/year.