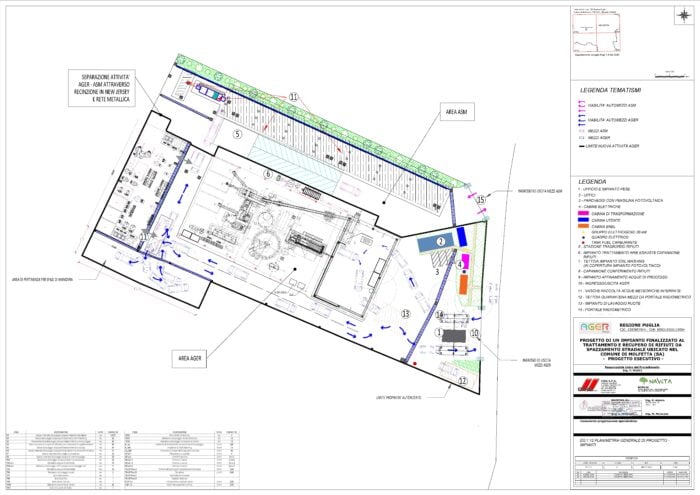

The plant operates a biological treatment for stabilizing the organic fraction (also called

“undersize resulting from MSW undifferentiated screening”) from the existing MSW

mechanical treatment plant. This is aimed at producing off-specification compost. The

plant also operates a composting treatment of the organic fraction downstream of

the separate collection of MSW. This is aimed at producing high-quality compost. The

process of biostabilization occurs within 60 concrete lanes with mobile steel coverage

and breathable fabric. The bottom of each lane is provided with a system for the

insufflation of the air that is necessary for the process. The air is uniformly distributed

through five parallel channels, which extend to the entire length of each composting

lane. During the process, temperature, humidity and interstitial oxygen are monitored,

and air insufflation is modulated on the basis of these measured parameters. A

significant aspect is related to the reduction of emissions into the atmosphere:

odorous substances are retained within the lanes by using breathable fabrics. During

the oxidation process of the putrescible fraction, the temperature increases due to the

degradation activity of the microorganisms, and the evaporation of interstitial water

forms a thin film in contact with the cloth itself. Such thin film, together with the small

weaving of the cloth (0.2 μm), constitutes a mechanical barrier against the odorous

molecules. Smaller molecules (O2, CO2, water vapor), instead, are free to transpire.

This prevents approximately 95% of the spores and pathogenic bacteria to be spread

in the air.

The off-specification compost product can be treated as biomass, and thermally

exploited, so as to produce energy that will receive financial incentives when released

into the national network.