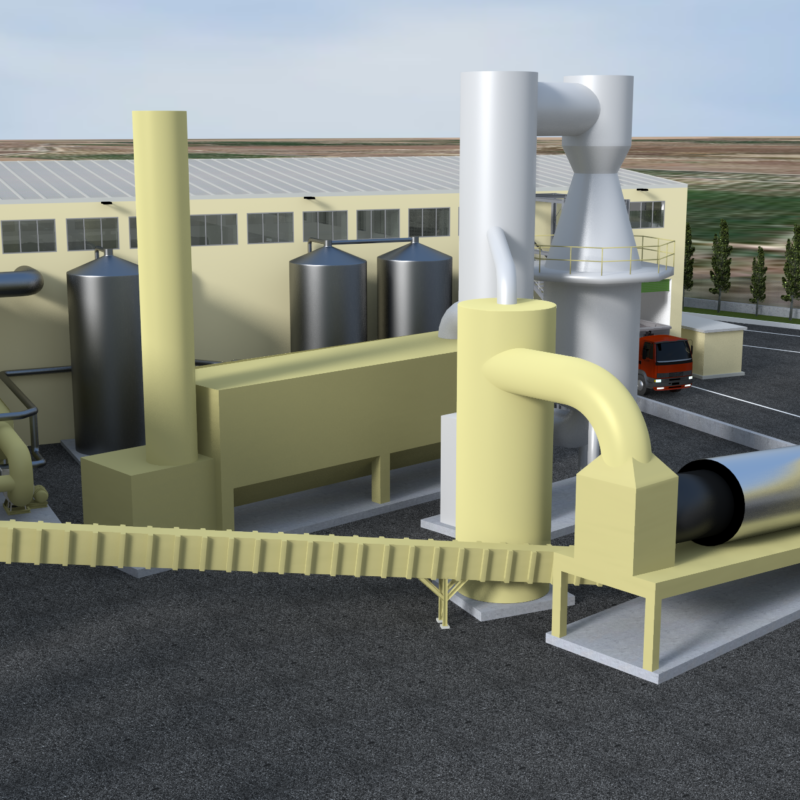

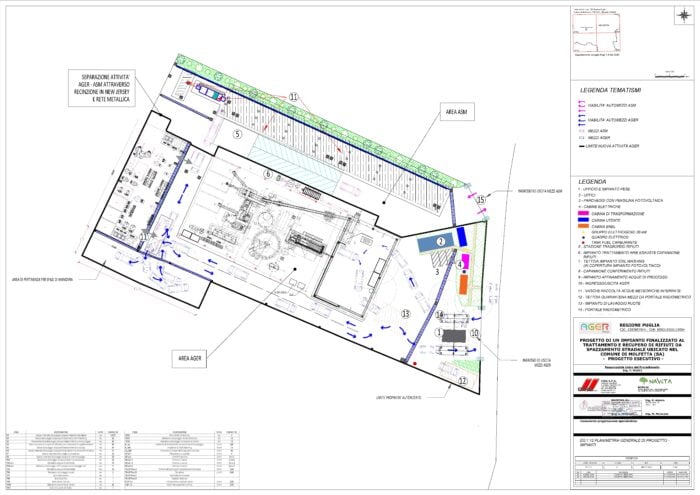

The combined facility for the contaminated soil treatment combines the advantages

of using the process of thermal desorption for the removal of organic contaminants

(i.e. hydrocarbons) to those resulting from the use of the inertization process for the

stabilization of the inorganic contaminants (i.e. heavy metals).

The thermal desorption system (with a potentiality of 100.000 tons/year) is able to

treat contaminated soils with operating temperatures below 650°C; it has the following

advantages, compared to other traditional systems of incineration of the contaminants:

the treatment doesn’t have emissions of dioxins and furans; the decontaminated soil

still retains the original mechanical properties and it can therefore be used for industrial

purposes; the treatment costs are certainly lower.

The inertization system (with a potentiality of 50.000 t/y) is based on the stabilization

process – that is used for decades – for the stabilization of hazardous contaminants within

a solid compact matrix which is also stable over time. Using the appropriate reagents,

cement and water the process also blocks the contaminants that are more dangerous and

difficult to treat, such as cromoVI, ammonia, arsenic and mercury.

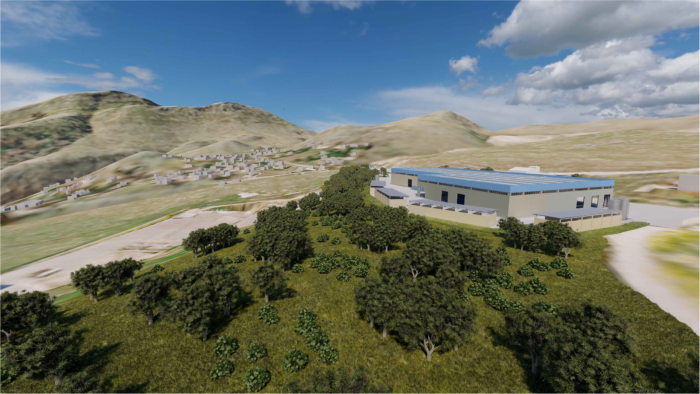

The facility offers clear advantages in terms of both treatment times (less than those of

other traditional systems) and economic, managing to convert hazardous waste into non-

hazardous. The soil remediation, which is often too expensive and environmentally costly,

is so encouraged.