Ensure availability and sustainable management of water and sanitation for all

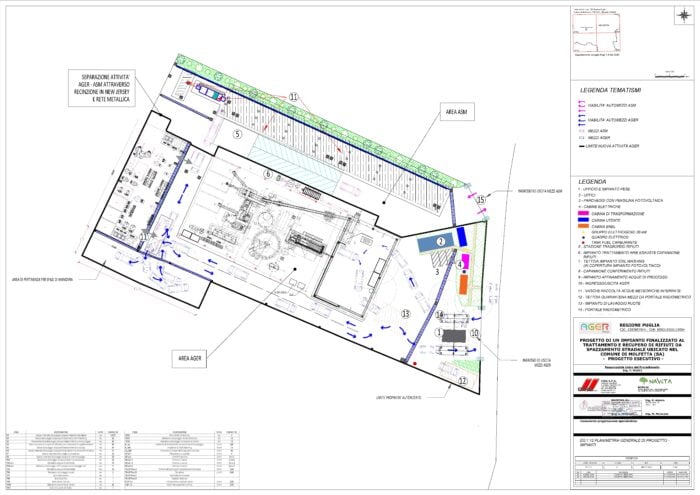

The detailed design involves the development of a treatment plant for the organic fraction of municipal solid waste (OFSMW) with the incorporation of an anaerobic digestion section.

Location

Civitavecchia, Rome (RM)

Data

Type of service:

Executive design

Designe period:

work in progress

Technical data

Total site surface:

79.700 m²

OFSMW treatment section:

Incoming organic waste: 100.000 t/year

Compost produced: 24.092 t/year

Waste: 1.971 t/year

End of waste:

Biomethane: 7.383.159 Nm³/ year

Sustainable development objectives | Agenda ONU 2023

The project, upon completion, will include a pre-treatment section where the incoming waste will undergo a pressing phase. The resulting liquor will feed into an anaerobic digestion section, where biogas will be produced and subsequently refined into biomethane. The digestate will then be directed to a solid-liquid separation section. The solid portion will be sent to the aerobic composting section, which involves treatment in biocells, a maturation phase, and a subsequent refinement phase aimed at producing compost. Meanwhile, the liquid portion will proceed to a treatment section equipped with a first stage of MBR (Membrane Bioreactor), a second stage of ultrafiltration and osmosis, and a third evaporative stage. The clarified effluent will be reused for industrial purposes.