Ensure availability and sustainable management of water and sanitation for all

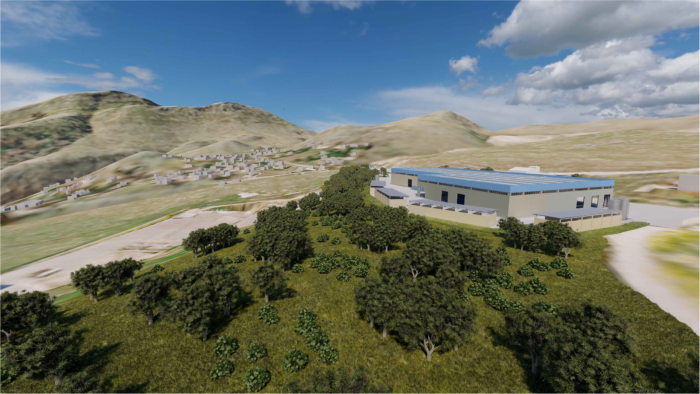

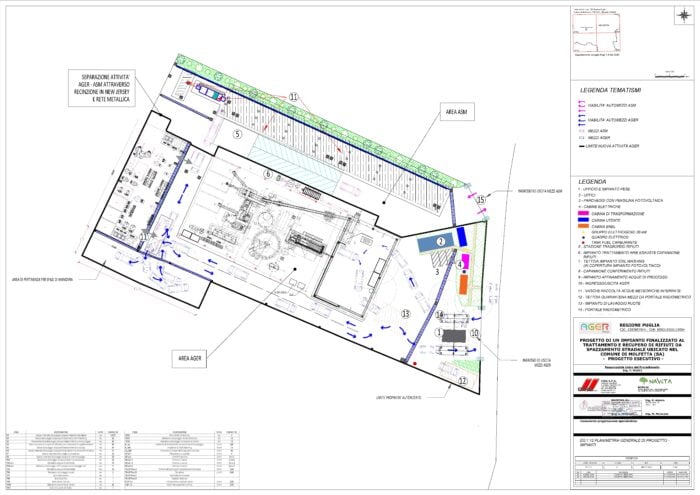

The plant is equipped with all the necessary structures and equipment to ensure the proper execution of composting operations for the organic matrices received, as well as to maintain an adequate level of safety for the plant itself and the surrounding areas.

The plant is authorized for the treatment and recovery (operations R13 and R3 as per Annex C of Legislative Decree 152/06 and subsequent amendments) of biodegradable organic waste as defined in Article 4 of the AIA decree (DDG n. 990 of 01/07/2015), with a maximum capacity of 45,000 tons/year, aimed at producing quality compost and natural fertilizers. The activities within the plant can be divided into the following phases:

- Conferment, storage, and mechanical pre-treatment of incoming waste;

- Accelerated aerobic biostabilization in biocells;

- Intermediate screening of the material;

- First maturation phase in aerated heaps;

- Final refinement and second maturation phase;

- Storage of finished product and oversize material.

To mitigate the environmental impacts associated with the treatment process at the plant, the following measures are implemented:

- Exhaust air treatment – designed for a flow rate of 280,000 m³/h; this system consists of three scrubbers, each equipped with two fans. The air is humidified and depolluted, and while passing through the biofilter, volatile organic compounds and odorous substances are removed within legal limits;

- Separate collection and management of rainwater, wastewater, and leachate;

- Adequate impermeabilization system – beneath all areas designated for the handling, storage, and treatment of compostable waste, which includes a leveling layer of foundation soil, protective geotextile, a 2.5 mm thick HDPE geomembrane, a drainage geocomposite (composed of geotextile, geogrid, and geotextile), a layer of aggregate for leveling on which industrial flooring will be constructed.