Ensure availability and sustainable management of water and sanitation for all

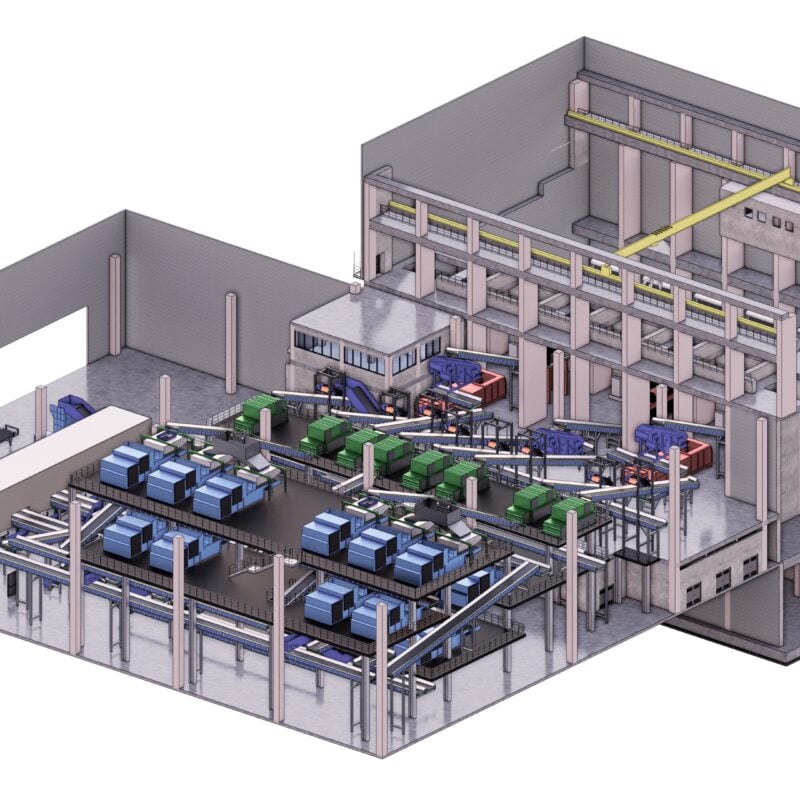

Today, the new regional objectives include the creation of highly automated lines that allow for the recovery of plastics sorted by polymer type, as well as ferrous and non-ferrous materials.

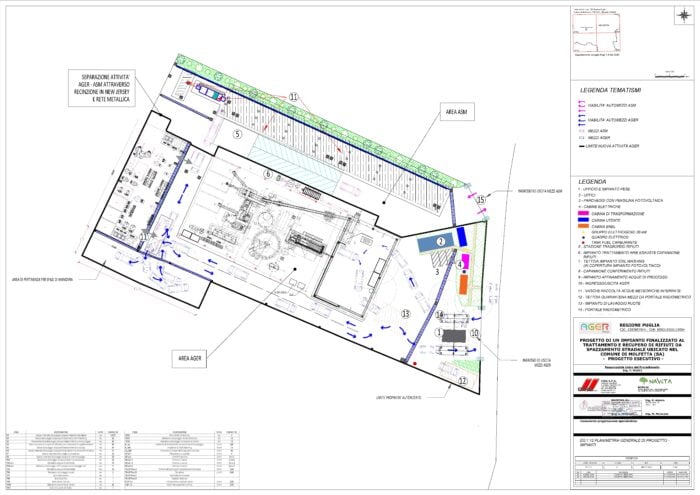

Location

Municipalities of Giugliano Tufino, Caivano, Naples (NA)

Data

Type of service:

Technical and economic feasibility

Design period:

Work in progess

Technical data

Super-fast line:

Composed of a primary shredder, a vibrating screen, a metal separation section, and a secondary shredder.

High material recovery lines:

Composed of a primary shredder, a vibrating screen, metal separation sections, an air separator, and several optical separators.

Recovered materials:

- PET, HDPE, PP, PS, PVC: 12%

- Ferrous and aluminum: 2%

- Fuel-derived waste (RDF): 46%

Sustainable development objectives | Agenda ONU 2023

The project currently under development aims at the revamping of the treatment lines of the STIR facilities in Tufino, Giugliano, and Caivano. Over the last decade, these facilities have ensured the treatment of unsorted waste.

Each line includes the use of air separation, optical separation, magnetic separation, and eddy current separation technologies. The project aims to achieve, based on current waste composition, a recovery of about 20% of the incoming material.

Mitigation works of environmental impacts related to the treatment process performed in

the plant are designed:

• exhaust air treatment, sized for a flow rate of 280.000 m³/h; this system consists of

3 scrubbers equipped with two electric fans each. The air is then humidified and

dedusted and in the passage through the biofilter also the volatile organic substances

and odorigene are cut down within the limits of the law

• separate collection and management of rainwater, wastewater and leachates;

• adequate waterproofing system below all areas for handling, storage and treatment

of waste composed as follows: layer of foundation ground regularization; WNW

protection; 2.5 mm thick HDPE geomembrane; drainage geocomposite (consisting of

WNW, geogrid and WNW); mixed layer of final regularization.